The Role of Welded Wire Mesh Panels in Industrial Applications

Introduction:

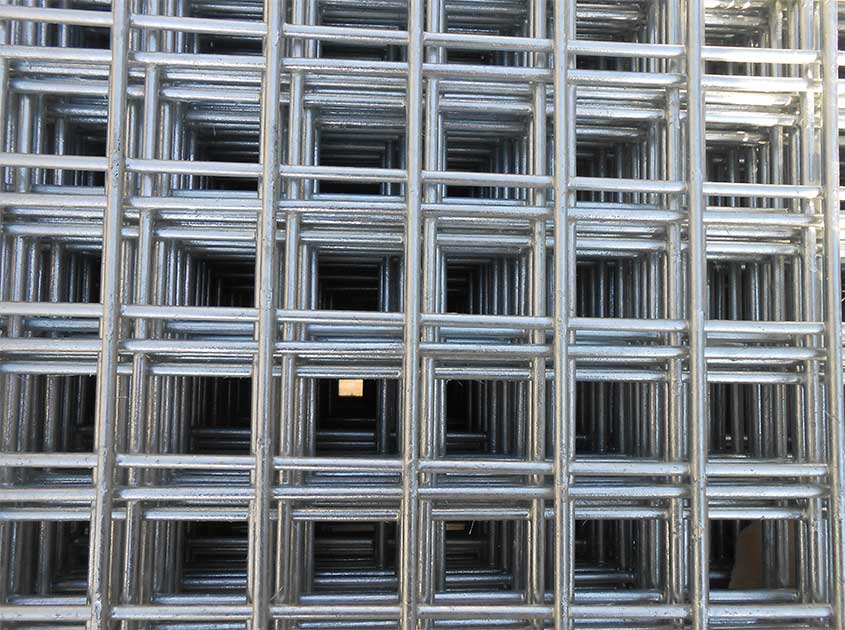

Welded wire mesh panels have become indispensable in various industrial applications, offering a range of benefits including strength, durability, versatility, and cost-effectiveness. In this article, we explore the significant role of welded wire mesh panels in industrial settings and examine how they contribute to improved efficiency, safety, and organization.

Material Handling and Storage:

Welded wire mesh panels are widely used in material handling and storage applications. They are commonly employed to construct racking systems, partitions, and cages for organizing and securing inventory, tools, and equipment. The open mesh design allows for easy visibility, ventilation, and accessibility to stored items. By utilizing welded wire mesh panels, industrial facilities can optimize space utilization, enhance inventory management, and improve workflow efficiency.

Machine Guards and Safety Enclosures:

Ensuring worker safety is paramount in industrial environments. Welded wire mesh panels are frequently employed in the construction of machine guards and safety enclosures. These panels create a protective barrier around machinery and equipment, preventing accidental contact with moving parts and reducing the risk of injuries. The mesh design allows for visibility and ventilation, enabling workers to observe machine operations and maintain a safe working environment.

Walkways and Platforms:

Welded wire mesh panels find application in the construction of elevated walkways and platforms within industrial facilities. Their sturdy construction and non-slip properties provide a safe and stable surface for workers to navigate elevated areas. The open mesh design allows for easy drainage, reducing the risk of slips and falls due to wet or slippery conditions. Welded wire mesh panels provide a cost-effective solution for creating elevated structures that enhance accessibility and operational efficiency.

Conveyor Belt Systems:

Conveyor belt systems are extensively used for material transportation in industrial settings. Welded wire mesh panels serve as an integral component in these systems. They can be utilized as belt support or containment sides, ensuring smooth and secure movement of materials along the conveyor. The panels' high strength and durability enable them to withstand heavy loads and provide consistent performance even in demanding environments.

Filtration and Separation:

Welded wire mesh panels are employed in industrial processes that require filtration and separation of materials. These panels can be utilized as screens or sieves to separate particles based on size or shape. The precise and uniform mesh openings of the panels enable efficient filtration and ensure consistent quality control in industries such as mining, agriculture, food processing, and pharmaceuticals.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China